The Axis Knee System: Affordable and Accessible Total Knee Replacement

May 10, 2019

By | May 10, 2019 | In The Spotlight, STII-Bridge

Source: https://news.oneexpert.gov.ph/in-the-spotlight/axis-knee-system-affordable-accessible-total-knee-replacement/

A knee replacement technology is now available to Filipinos at half the price of the world market.

With funding from the Department of Science and Technology-Philippine Council on Health Research and Development, the Axis Knee System, in the Philippines market since July 2015, was developed by Dr. Ramon Gustilo of Negros Oriental.

Knee implants need to be aligned right relative to the patient’s bone and the procedure needs specialized skills. Gustilo’s knee replacement technology enables orthopedic doctors to do the procedure without specialized training that often takes one year. One reason for the high cost is that currently, the knee implants available in the Philippines are all imported from the United States and Europe. These implants cost between P100,000 to P120,000.

Gustilo’s Axis Knee System brings the cost of a knee replacement to P60,000 in government orthopedic hospitals and P70,000 in private hospitals, or about half the cost of imported knee implants. The cost is drastically reduced because the implants are made locally by Gustilo’s Orthopaedic International, Inc., a company with more than 20 years of experience in designing and manufacturing orthopedic implants.

Another reason for the high cost is that total knee replacement is a technically demanding procedure that requires general orthopedic surgeons to undergo a one-year fellowship training abroad. The rigorous requirements and cost of getting into a fellowship program has limited the number of Filipino surgeons with joint replacement fellowship training. Thus, total knee replacement surgery has been confined to the large, mostly private, hospitals in the major cities where joint replacements surgeons tend to have their practice.

There are only 60 orthopedic surgeons with the training and qualification to do joint replacement surgery in the Philippines where only 2,000 procedures are conducted each year. The Axis Knee System technology should increase the number of qualified surgeons from a pool of about 700 local orthopedic surgeons.

It is estimated that over a million total knee replacement surgeries are performed worldwide each year for the treatment of arthritic conditions. Over a half-million of these procedures are performed in the United State alone. In the Philippines, there are an estimated 180,000 candidates for total knee replacement annually.

Arthritis of the knee affects hundreds of thousands of Filipinos every year. Many of these patients are the elderly who suffer from disabling knee pain that prevents them from moving around and going about their daily activities.

When conservative treatment methods have been exhausted, total knee replacement is the only recourse wherein an artificial knee joint replaces the worn-out cartilage lining the joint surfaces. The surgical procedure allows pain-free movement.

However, the high cost of the implants and the limited number of surgeons who can perform the surgery limits the accessibility of this treatment to only a small percentage of Filipinos.

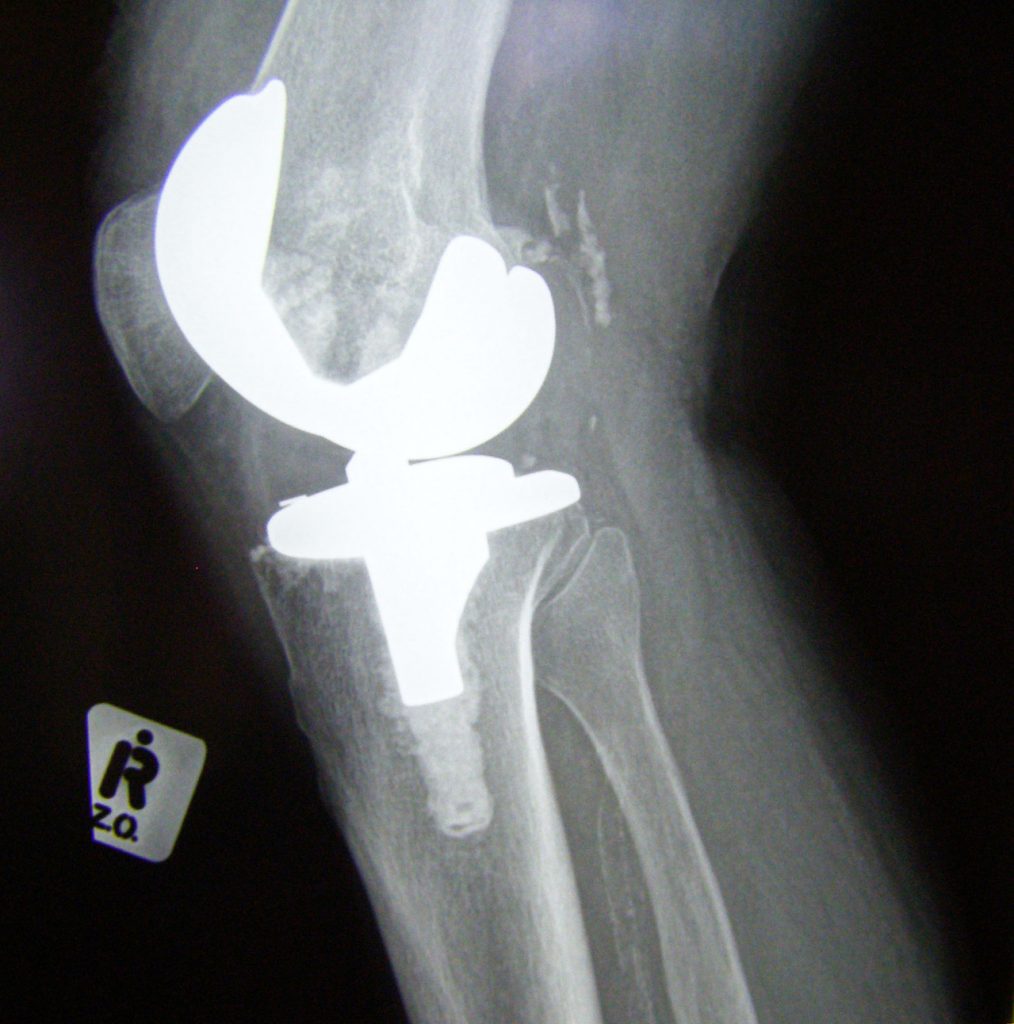

Knee replacement is one of the most successful orthopedic procedures worldwide and has been performed for over four decades to eliminate pain, reduce disability and improve the quality of life of arthritic patients. The surgeon cuts off damaged cartilage and bone from the weight-bearing surfaces of the knee and replaces them with artificial components made of metal and plastic.

Although many different designs and materials are currently used in knee replacement surgery, the implants basically consist of thee components: the femoral (thigh) component made of a highly polished metal alloy, the tibial (shin) component made of a durable plastic (polymer) sometimes held in a metal tray, and the patellar (knee cap) component also formed from plastic.

These components are positioned and fixed to the bones to eliminate pain and restore the alignment and function of the knee.

A well-designed knee implant that is implanted correctly lasts up to 20 years. When the implants are not well-aligned relative to what is called the “mechanical axis” of the leg, the knee replacement can fail rapidly. A misaligned knee implant may need to be replaced, sometimes in as short as two years from the initial surgery.

The mechanical axis is an imaginary line connecting the center of the hip joint, the center of the knee joint and the center of the ankle joint. The center of the hip, the center of the artificial knee and the center of the ankle should all lie along a straight line when viewed from the from and from the side of the leg.

One of the challenges in total knee replacement surgery is how to identify the mechanical axis. Computerized navigation systems can cost up to P20 million and even cumbersome to use in surgery. There are only a few large hospitals in the Philippines that are equipped with a computerized navigation system, and use of such system will add at least P20,000 to the cost of surgery.

The Axis Knee research team designed a very innovative device that locates the mechanical axis without using navigation technology. The patent-pending device, called the Mechanical Axis Finder, is an inexpensive, portable, and reusable and mechanical device that can be placed directly on the surgical table. Using the device properly aligns the mechanical axis.

At the same time, the research considered the anatomic peculiarity of Asian knees as compared to Caucasian knees. Most knee systems in the market are manufactures by Western companies and designed based on Caucasian knee dimensions. Studies have shown that Asian knees are generally narrower and therefore are not optimally matched with Caucasian implants.

The Axis Knee implants developed by the research project have sizes and dimensions that can cover both Asian as well as Caucasian knees.

The design and development of the Axis Knee System has been completed. The required biomechanical tests have been performed and production processes have been validated. It is now available to Filipinos.

Written by:

Jude L. Sasing

Orthopaedic International Inc.

Published by:

Department of Science and Technology-Science and Technology Information Institute (DOST-STII)